About Spun-Lace Nonwoven

2017-06-26 15:33:23

The aged practice for consolidating a web is mechanical bonding process, and this process entangles the fibers to provide better strength to the web. Under mechanical bonding, there is several ways, but out of them, one of most broadly used method is spun-lacing or hydro-entanglement method.

There are several diverse specific terms, which are used for Spunlace nonwoven as jet-entangled, water entangled, hydro-entangled or hydraulically needled. However, the term, Spunlace, is most popular in the nonwoven industry.

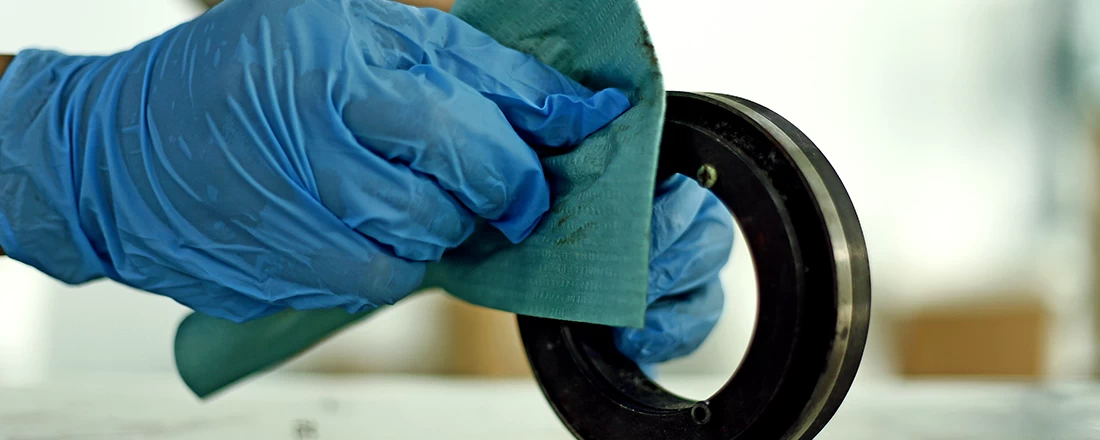

The Spunlace process is a nonwovens manufacturing system that employs jets of water to entangle fibers and thereby provide fabric integrity.

After the production of Spunlace fabric, it can be further undergone to finishing process according to the customers need. The main finishing done are mainly dying or printing. It can also be treated with binders to permit for wash sustainability. In some special cases, fire retardants can be applied to Spunlace fabric to resist burning. Further antimicrobial agents can treat the Spunlace fabric to enhance resistance against microorganisms.

In general, fibres with low bending modulus entangle more easily than fibres with high bending modulus. The fibre length is directly proportion to the tie point or entangle areas & inversely proportional to the fabric strength. Therefore, compromise is done for the fibre length. It is seen that 1.8-2.4 cm length of fibre gives best result.