The usage of wood pulp spunlace compound nonwoven fabrics

2017-08-08 11:51:03

Non-woven fabrics can be divided according to the production process:

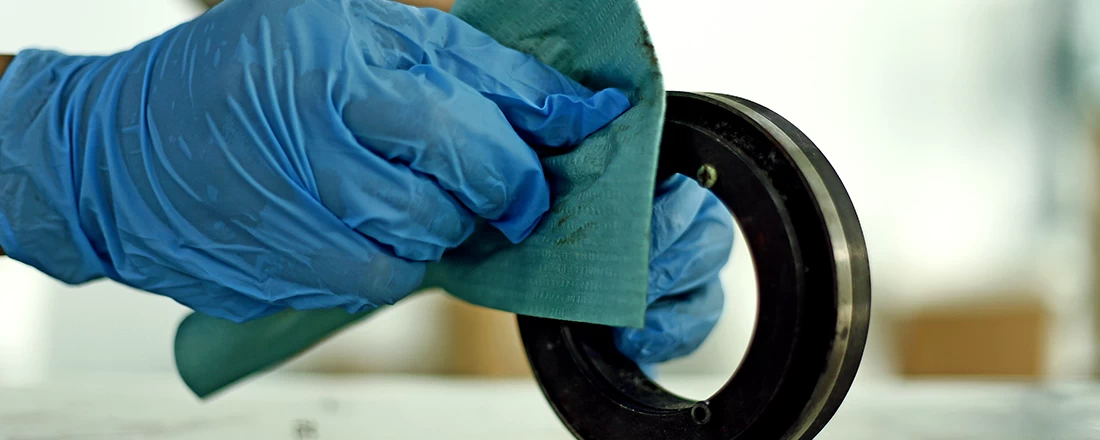

1. Water spiny non-woven fabric: it is to inject the high pressure fine water into a layer or multi-layer fiber network, so that the fibers are entangled together, thus reinforcing the fiber net and having some strength.

2. Heat and non-woven fabric: refers to the addition of fibrous or powdery hot melt adhesion reinforcement materials in the fiber net, and the fiber net is then heated to melt and harden into a cloth.

1. Water spiny non-woven fabric: it is to inject the high pressure fine water into a layer or multi-layer fiber network, so that the fibers are entangled together, thus reinforcing the fiber net and having some strength.

2. Heat and non-woven fabric: refers to the addition of fibrous or powdery hot melt adhesion reinforcement materials in the fiber net, and the fiber net is then heated to melt and harden into a cloth.

3. The pulp airflow is a non-woven fabric: it can be called clean paper and dry method.It is used as a network technology to loosen the wood pulp fiberboard into a single fiber state, and then use airflow method to make the fiber to be condensed into the net curtain, the fiber net is reinforced into cloth.

4, wet nonwoven: fiber raw material is placed in a water medium opening into single fiber, at the same time make different fiber ingredients, made from fiber suspension slurry, suspension slurry to the network, fiber under wet condition into a network to reinforce into cloth.

5, spun-bonded non-woven fabric: is in polymer has been after extrusion, stretching to form a continuous filament, filament laid into the net, fiber network by self bonding, hot glue, chemical bonding or mechanical reinforcement method, make fabric non-woven fabrics.

6. Melt non-woven fabrics: the process of the process: polymer feeding - melting extrusion - fiber formation - fiber cooling - into mesh - reinforcement into cloth.

4, wet nonwoven: fiber raw material is placed in a water medium opening into single fiber, at the same time make different fiber ingredients, made from fiber suspension slurry, suspension slurry to the network, fiber under wet condition into a network to reinforce into cloth.

5, spun-bonded non-woven fabric: is in polymer has been after extrusion, stretching to form a continuous filament, filament laid into the net, fiber network by self bonding, hot glue, chemical bonding or mechanical reinforcement method, make fabric non-woven fabrics.

6. Melt non-woven fabrics: the process of the process: polymer feeding - melting extrusion - fiber formation - fiber cooling - into mesh - reinforcement into cloth.

7. Acupuncture non-woven fabric: it is a kind of dry method non-woven fabric, which is used to use the puncture of the needle to strengthen the loose fiber net into cloth.

8, stitch-bonded nonwoven cloth, is a kind of dry non-woven fabrics, sewing lawmakers is the use of warp knitted coil structure of fabric, yarn, textile materials (such as plastic sheets, plastic thin metal foil, etc.) or their combination for reinforcement, made from non-woven fabric.

Non-woven use

· its main USES can be roughly divided into:

8, stitch-bonded nonwoven cloth, is a kind of dry non-woven fabrics, sewing lawmakers is the use of warp knitted coil structure of fabric, yarn, textile materials (such as plastic sheets, plastic thin metal foil, etc.) or their combination for reinforcement, made from non-woven fabric.

Non-woven use

· its main USES can be roughly divided into:

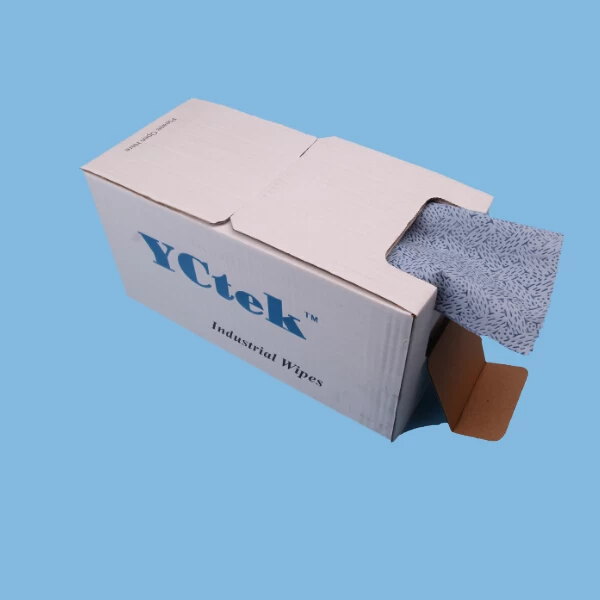

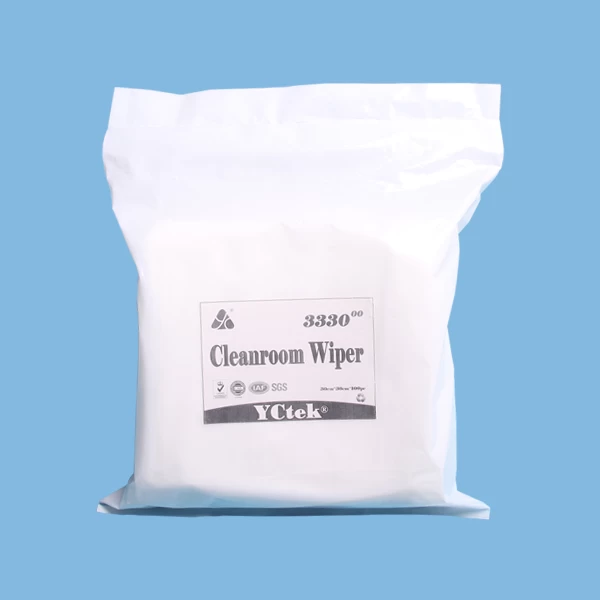

(1) the medical and health with non-woven fabric: gown, protective clothing, XiaoDuBao cloth, mask, diapers, civil cloth, wiping cloth, wet towel, magic towel, soft towel roll, beauty products, sanitary napkin, sanitary pads and disposable sanitary articles, etc.;

(2) household decoration with non-woven fabrics: wall cloth, tablecloth, bedsheet, bedspread, etc.;

(3) non-woven fabrics: lining, adhesive lining, flocculation, shaping cotton, various synthetic leather soles, etc.

(4) industrial non-woven fabrics;Filter materials, insulating materials, cement bags, earthwork cloth, coating cloth, etc.

(5) non-woven fabrics for agriculture: crop protection cloth, seedling cloth, irrigation cloth, curtain of insulation curtain, etc.;

(6) other non-woven fabrics: space cotton, insulation and sound insulation, oil absorbing felt, cigarette filter, bag bag, etc.

Nonwoven features

· non-woven fabric breaks through the traditional textile principle, and has the characteristics of short process, fast production speed, high yield, low cost, wide use and many sources of raw materials.

(2) household decoration with non-woven fabrics: wall cloth, tablecloth, bedsheet, bedspread, etc.;

(3) non-woven fabrics: lining, adhesive lining, flocculation, shaping cotton, various synthetic leather soles, etc.

(4) industrial non-woven fabrics;Filter materials, insulating materials, cement bags, earthwork cloth, coating cloth, etc.

(5) non-woven fabrics for agriculture: crop protection cloth, seedling cloth, irrigation cloth, curtain of insulation curtain, etc.;

(6) other non-woven fabrics: space cotton, insulation and sound insulation, oil absorbing felt, cigarette filter, bag bag, etc.

Nonwoven features

· non-woven fabric breaks through the traditional textile principle, and has the characteristics of short process, fast production speed, high yield, low cost, wide use and many sources of raw materials.