Meltblown cloth feature and application

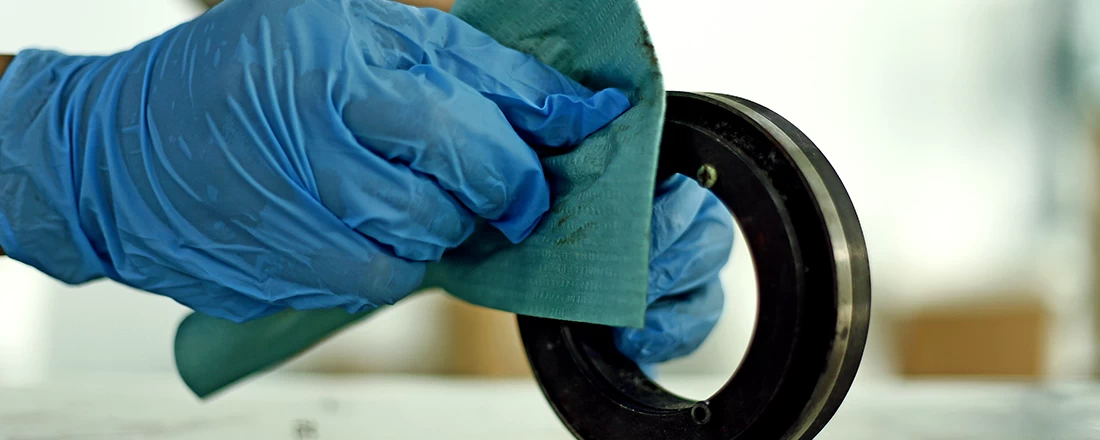

Meltblown cloth is mainly polypropylene as the main raw material, the fiber diameter can reach 1 ~ 5 micron.With many voids, fluffy structure and good anti-folding ability, these superfine fibers with unique capillary structure increase the number and surface area of fiber per unit area, so that the melting spray cloth has a good filtering, shielding, insulation and oil absorption.Can be used for air, liquid filtration materials, isolation materials, absorption materials, mask materials, warm materials, oil absorption materials and wiping cloth and other fields.

Application scope:

(1) medical cloth: operating clothes, protective clothing, disinfectant cloth, masks, diapers, women's sanitary napkins, etc.;

(2) domestic decoration cloth: wall cloth, table cloth, bed sheet, bedspread, etc.;

(3) clothing fabrics: lining, adhesive lining, flocs, shaping cotton, various synthetic leather undercloth, etc.;

(4) industrial cloth: filtration material, insulation material, cement packing bag, geotextile, covering cloth, etc.;

(5) agricultural cloth: crop protection cloth, seedling cloth, irrigation cloth, heat preservation curtain, etc.;

(6) others: space cotton, insulation materials, linoleum, smoke filter, tea bags, etc.

The meltblown cloth filter material is randomly distributed by polypropylene microfiber bonded together, the appearance is white, flat, soft, the fineness of the material fiber is 0.5-1.0m, the random distribution of the fiber provides more opportunities for the thermal bonding between the fibers, so that the melt spray gas filter material has a larger specific surface area, higher porosity (≥75%).Through high pressure electret filtration efficiency, the product has the characteristics of low resistance, high efficiency and high dust capacity.