From PP to non-woven cloth to mask, do you understand the basic knowledge?

From PP to non-woven cloth to mask, do you understand the basic knowledge?

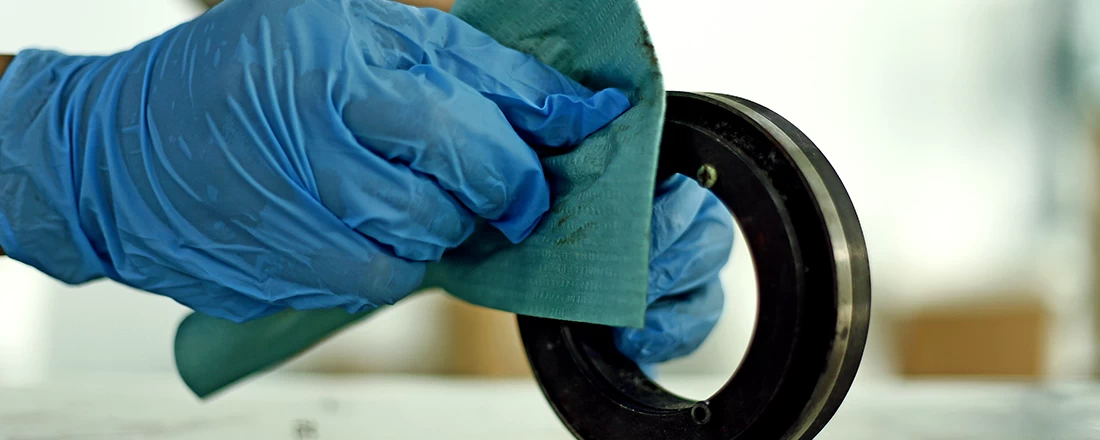

Masks are non-woven fabrics, which are non-woven fabrics as opposed to textile fabrics, and are composed of directional or random fibers.

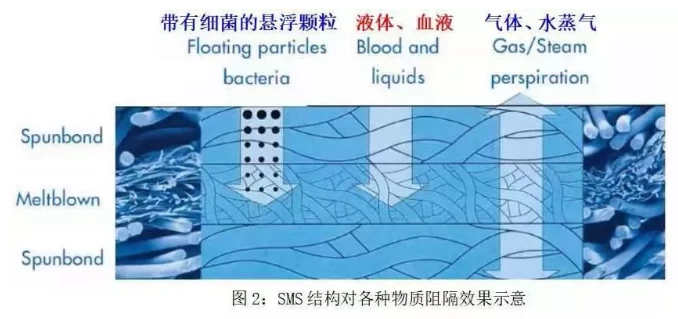

Medical masks are generally multilayered, commonly referred to as SMS (2 S and 1 M layers).Currently, the highest number of layers in China is 5, namely SMMMS(2 S and 3 M layers).

What is SMS ~

Here, S stands for Spunbond layer. The diameter of the fiber is relatively thick, about 20 microns (m). The main function of the 2 S Spunbond layers is to support the entire non-woven fabric structure, which has no great effect on the barrier.The most important part of the mask is the barrier layer or Meltblown layer M(Meltblown layer). The diameter of the molten spray layer is relatively thin, about 2 microns (M), so it is only one tenth of the diameter of the spunbonding layer, which plays a vital role in preventing bacteria and blood penetration.

General medical masks usually use melt spray cloth weighing 20 grams, N95 cup masks use melt spray cloth weighing 40 grams or more.

According to the statistics of China Industrial Textile Industry Association, by the end of 2018, there are 1,477 domestic spunbonded production lines, 65 more than that of the previous year, with a year-on-year increase of 4.6%, among which, PP spunbonded non-wovens production line is increased by 3.38%, SMS composite production line by nearly 13%, and PET spunbonded non-wovens production line by 9.32%.The number of companies with annual output exceeding 50,000 tons also increased from 2017.Spunbonded enterprises are speeding up their development towards scale, intensification and high-end to meet the market demand of product upgrading and technology upgrading.

Since 2018, many domestic enterprises have developed their products in the direction of lighter, thinner and higher performance, and achieved good results.SSMMS spunbonded/molten shotcreting composite process 600m/min or above high speed operation;About 10 grams per square meter super soft light stable quality products continue to emerge.

Where does SMS non-woven fabric come from

SMS non-woven fabrics are mainly made from polypropylene PP(with natural bacteriostatic properties and hydrophobicity), and the diameter of the fibers can reach 0.5-10 microns. These ultrafine fibers with unique capillarity increase the amount and surface area of the fibers per unit area, thus making the melt-sprayed fabrics have good air filtering properties and are relatively good mask materials.

At present, there are three main processes for manufacturing SMS products (SMS non-woven fabric) : "one-step process", "two-step process" and "one-and-a-half step process".

One-step features is the use of raw materials section of this process, using two spun-bonded, melt-blown technology, direct spinning raw material after melting into the nets, as long as reasonable arrangement of different process of spinning systems engineering, and can make the products with different structure, each layer fabric laminated composite, is usually with a hot rolling mill consolidation into cloth."One-step method" is characterized by melting directly spinning into a net, the state of each spinning system can be independently adjusted, the production process of strong control, good health conditions, high speed, can adjust the proportion of each layer of fiber net, can produce SMS type products of various specifications, is the mainstream technology today.

Two-step process: When using the two-step process to produce SMS products, the finished products of spunbonded cloth and melt-sprayed cloth are unrolled in a certain order, and then laminated in a sequence, and then consolidated with a hot mill to form SMS products.The two-step method is characterized by simple equipment and low cost.In fact, the "two-step" process is the widely used lamination composite technology, but also can be composite of other materials, with different other materials, and with different methods, such as ultrasonic, hot melt adhesive three layers of materials together.

One-and-a-half step method: in two-step method, it is also possible to replace the molten spraying cloth product with the molten spraying layer fiber net produced in the field, thus derived the so-called "one-half step method" composite process.The spunbonded cloth is used as the bottom layer and the surface layer by two unwinding devices, and the melt spraying fiber net of the middle layer is directly spun into a net by the melt spraying system, laid on the bottom layer of the spunbonded cloth, and then covered with the upper layer of the spunbonded cloth, it is better to use a hot mill consolidated into SMS products.