An Overview of Industrial Cleaning Wipes

2017-05-05 16:09:12

When selecting industrial cleaning wipes for your plant, factory, or workspace there are two categories from which to select – dry or wet wipes. Dry are used primarily for absorbent purposes – cleaning spills or wet surfaces; the latter are for waterless cleaning of dust, dirt, grease, or chemicals.

Reusable dry rags are one of two basic types of dry wipes from which to choose. Shop rags are used, washed, and then reused. These rags can be repurposed from cloth or woven specifically as rags. Generally, these rags are screened for quality during the washing process. However, metal shavings and other particles can remain even after screening and washing. In most situations, the service of washing and providing reusable rags is contracted out with another company, making the primary advantage of using reusable rags convenience and ease.

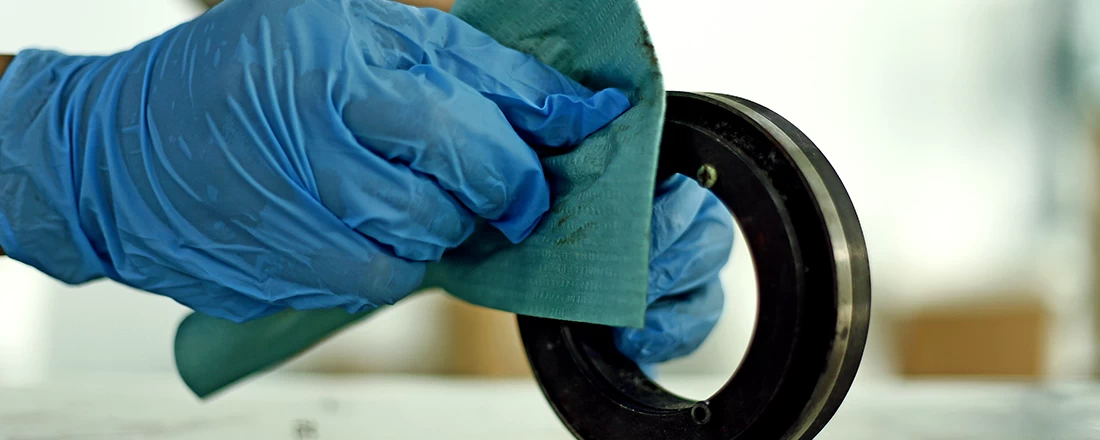

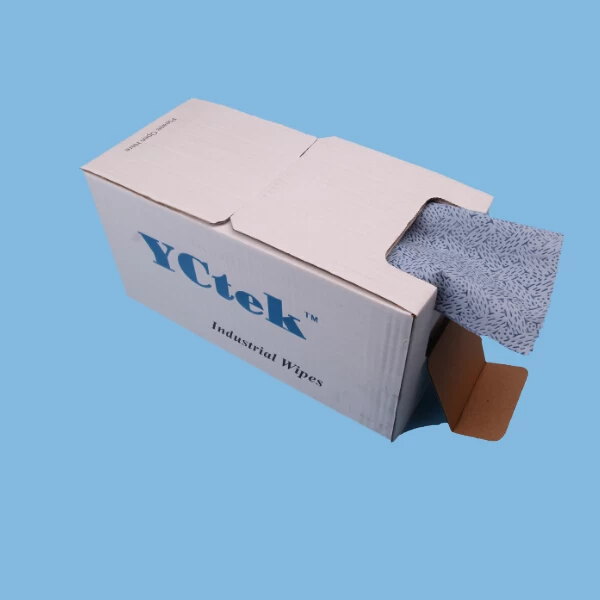

Disposable wipes are the second type of dry wipes. Ranging from light to ultra-duty, disposable wipes are used for a range of applications, from cleaning gears or sprockets, to wiping down the surface of a counter. Wipes can be economized at cost per toss to minimize spending, however they can lend themselves to waste if not used appropriately. The primary advantage of disposable wipes is that they relieve contamination concerns.

Like disposable dry wipes, premoistened wet wipes come in a variety of durabilities to meet the demand of their application. Premoistened wipes can be manufactured to be general, all-purpose cleaners, or specifically designed to neutralize things like battery acid or to clean up mercury. There are also premoistened hand-cleaning wipes, even wipes for removing adhesives. The advantage of premoistened wipes are two-fold. First, they don’t require water so can therefore be used anywhere, including places without immediate access to water. Secondly, they are designed with a specific purpose in mind, making them highly effective.