The practical application direction of industrial wiping cloth

2017-08-09 15:47:05

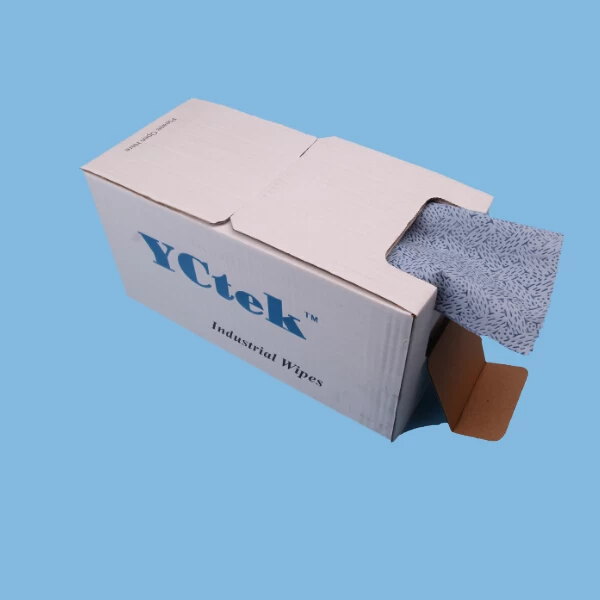

Traditional wipe products raw materials is more old cloth, textile leftover material, source of confusion, the quality is not stable, size is not unified, bibulous oil absorption is poor, dust off rub off easily, no fixed packaging, cleaning efficiency is low, artificial cost is high, and easy to damage equipment and product surface.

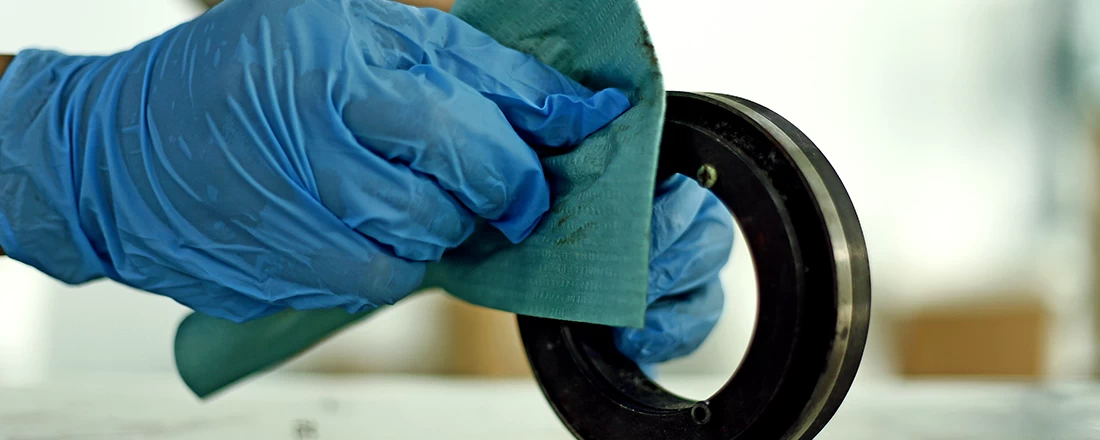

Cleanroom Wiper is a kind of widely used in electronic, optical, biological, medical and other fields of cleaning and wiping materials, according to the cloth wipe fiber cloth can be divided into polyester cloth, microfiber cloth, cotton cloth, non-woven cloth fiber (wipe fiber paper), etc.Cotton fiber non-woven fabric is made of 100% cotton and is made of pure natural raw materials. (the structure of cotton fiber is shown in FIG. 2-4).It has super moisture absorption and moisture, antistatic, long fiber and no adhesive.High temperature resistance, generally 260 to 300 degrees.Both environmental protection and excellent use performance are mainly used for the general cleaning requirements of equipment maintenance and products under controlled environment of higher level.Polyester dust-free cloth is made of 100% continuous polyester filament filament, which can resist wear, effectively prevent dust and fiber distribution, and has excellent absorption performance and extremely low ion residue.Ultrafine fiber dust-free cloth is made of ultrafine fiber knitwear or machine woven to be compared to general polyester dust-free cloth, with better softness and preventing surface abrasion ability.The four sides adopt laser cutting edge heat-sealing technology to prevent dust particles and fiber scattering.The exact name of the clean non-woven fabric for Class10 ~ 100 (iso4-5) shall be non-woven, or non-woven.We usually call it dust-free wiping paper, also known as dust-free paper.Strong absorption, but lack of softness.Dust-free cloth surface soft, easy to wipe sensitive surface, do not lose dandruff, have good cleanliness, absorb water.The cleaning and packaging of the products are finished in the dust-free workshop.The removal of trace pollutants in the critical clean environment can be accomplished well, which is the most effective cleaning tool in the clean room.There are also different levels and specifications for the current changing industrial demand.Such as liquid crystal wiping cloth, chip wiping cloth, CD wiping cloth and battery wiping cloth and so on.Liquid crystal wiping cloth, mainly used for LCD screen cleaning, need to wear away, durable, no debris, no fog.It's a must-have product for mobile phone makers.It is usually the main material with polyester super fine fiber.Chip wiping cloth, mainly used for the polishing of precision components such as chip, need to be careful when wiping, this requires dust-free absorbent water absorption capacity, and the ability to prevent static electricity.Optical disc wiping cloth is mainly used for hard disk production. As the SSD hard disk comes up, the price of disc wiping cloth is getting lower and lower.Battery wash cloth is suitable for all kinds of cell is wiped, silicon silver pulp wipe wipe, photovoltaic workshop professional equipment maintenance, etc., precision instrument assembly, water absorption capacity agent, eliminate laboratory apparatus and equipment cleaning, printing printing machine cleaning, LCD and plasma screens.Ultra fine fiber wiping cloth is a necessity for clean room and cleaning operation.High strength, toughness, and strong wet strength, anti-acid, alkali resistance and solvent resistance.Ultra-fine fiber wiping cloth has ultra-low dust rate and ion analysis rate, almost no dust, strong water absorption oil-absorbing surface soft, not scratch by wiping. So now the manufacturers have to subdivide the dust-free cloth market according to the different market demands, only in this way, can we have a place in the market faster.